In the ever-evolving world of manufacturing, where precision and efficiency are the lifeblood of success, the importance of innovative grinding room designs cannot be overstated. As industries strive to meet the demands of modern production, the grinding room emerges as a critical space, where raw materials are transformed with precision into the components that fuel our daily lives. Yet, while this room is pivotal, it often remains overshadowed by more visible facets of manufacturing. Today, we invite you to delve into the untapped potential of grinding room innovations—a journey that promises not only enhanced efficiency but also unprecedented precision, setting a new standard for industrial excellence.

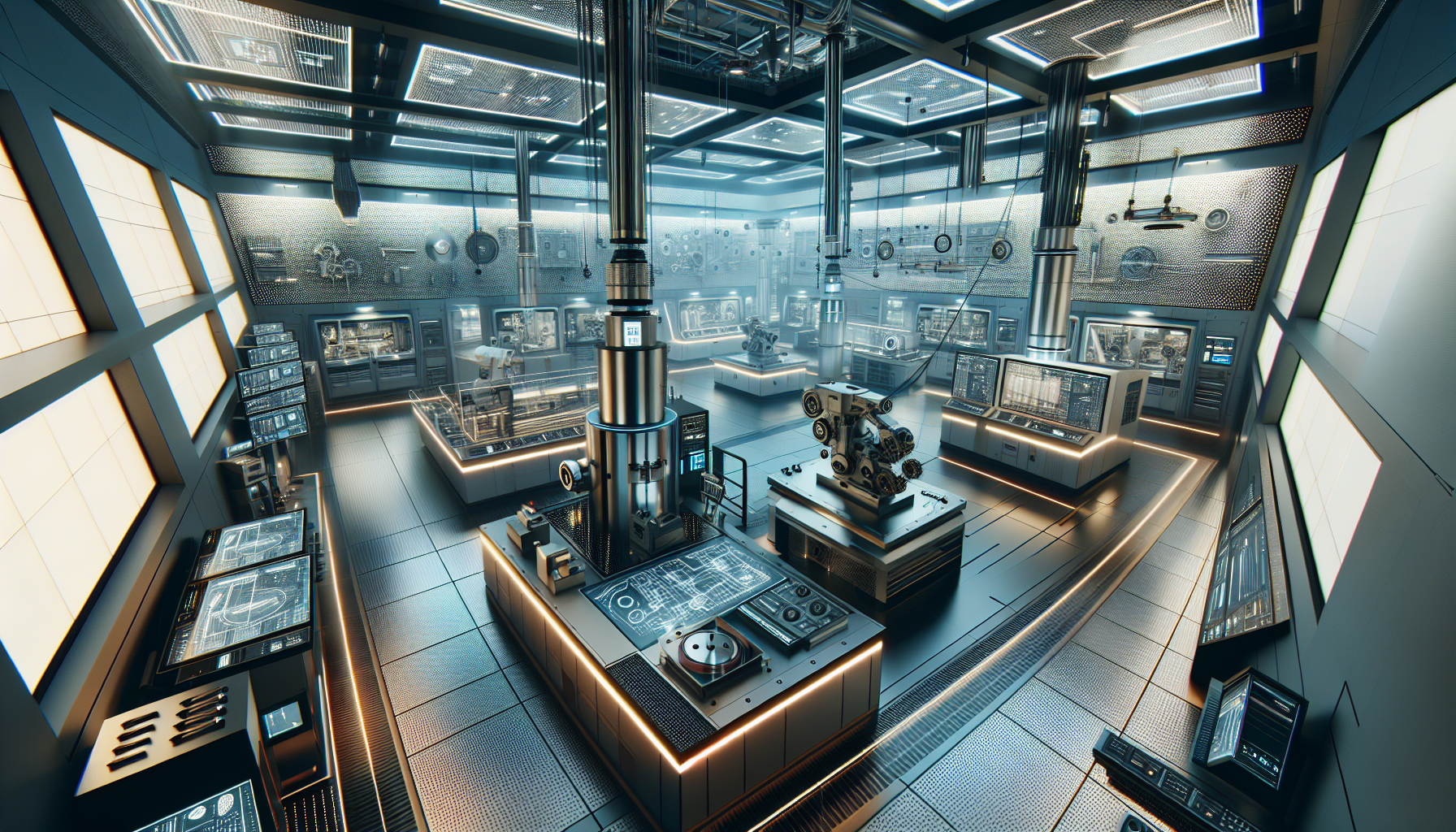

Imagine walking into a grinding room that feels more like a seamless extension of innovation itself. 🏭 Gone are the days of cluttered, noisy spaces that hinder productivity and compromise quality. Instead, picture a harmonious blend of advanced technology, ergonomic design, and sustainable practices all working in concert to elevate the manufacturing process. This is not a distant dream but an attainable reality, as industries increasingly recognize the transformative power of reimagining these crucial spaces. From the integration of smart technologies that optimize every millimeter of material to ergonomic layouts that prioritize worker safety and comfort, the future of grinding rooms is bright and brimming with possibilities.

In this comprehensive exploration, we will uncover the key components that define cutting-edge grinding room designs, offering insights into how these innovations can be tailored to meet the specific needs of various industries. We will examine the role of automation and digitization in streamlining processes, discuss the importance of sustainable practices in reducing environmental impact, and highlight the ways in which ergonomic considerations enhance both productivity and worker well-being. As we navigate through these topics, it becomes increasingly clear that unlocking the potential of grinding room designs is not merely an option but a necessity for those seeking to thrive in a competitive landscape. So, join us as we embark on this enlightening journey, paving the way for a future where efficiency and precision are not just goals, but standard practices in every grinding room across the globe. 🌍

Understanding the Basics of Grinding Room Designs

Grinding rooms are integral parts of any manufacturing process that involves the machining of materials to achieve specific shapes and sizes. The design of a grinding room can significantly impact both efficiency and precision in the manufacturing process. At its core, a grinding room is a controlled environment where grinding machines and tools are used to finish parts to exact specifications. These rooms are not merely about housing machinery; they represent a synergy between space, technology, and human skill to achieve optimal outcomes.

The fundamental components of a grinding room include the machines, workstations, safety equipment, and often a dust extraction system to maintain a clean environment. Each of these elements must be strategically planned and implemented to minimize waste and maximize productivity. Understanding the spatial arrangement, workflow, and the type of materials being processed is critical to designing an effective grinding room. For instance, high-precision grinding requires more controlled conditions compared to standard operations, often necessitating tighter environmental controls and advanced technology.

There are numerous types of grinding processes, including surface grinding, cylindrical grinding, and centerless grinding, each requiring specific equipment and room setups. Surface grinding involves the use of a rotating abrasive wheel to produce a smooth finish on flat surfaces, whereas cylindrical grinding is used for shaping the outside of an object. On the other hand, centerless grinding involves removing material from the workpiece without the need for clamping, thus offering higher throughput. Deciding on the appropriate grinding process involves evaluating the material characteristics, required precision, and production volume.

Innovative Approaches to Grinding Room Design

Innovation in grinding room design often revolves around integrating new technologies and optimizing the existing layout to improve efficiency. One significant trend is the use of automation and robotics to streamline operations. Robotic arms can handle repetitive tasks with precision, reducing human error and increasing throughput. Automation also facilitates real-time monitoring and adjustments, ensuring that the grinding process remains optimal. This technology integration allows for continuous operation, further increasing productivity.

Another innovative approach is the use of modular design in grinding rooms. Modular design involves creating flexible layouts that can be easily reconfigured to adapt to changing production needs. This flexibility is crucial in industries where product lines frequently change or evolve. Modular systems can include movable walls, adjustable lighting, and interchangeable workstations. This adaptability not only saves time and resources but also reduces downtime associated with retooling and setup changes.

Sustainability is also a growing concern in manufacturing, and grinding rooms are no exception. Implementing energy-efficient machinery and optimizing resource use can significantly reduce the environmental footprint of grinding operations. For instance, installing energy-efficient lighting and utilizing machines that consume less power are straightforward strategies to enhance sustainability. Additionally, advanced dust extraction and air filtration systems can help maintain a healthier work environment, reducing the need for ventilation and energy consumption.

Comparing Traditional and Modern Grinding Room Designs

The evolution from traditional to modern grinding room designs highlights significant advancements in technology and efficiency. Traditional grinding rooms were often characterized by heavy, manually operated machines and a reliance on skilled labor to achieve precision. These rooms required significant space for machine operations and manual handling of materials, leading to longer processing times and higher labor costs. The emphasis was primarily on achieving desired specifications rather than optimizing workflow or resource use.

In contrast, modern grinding rooms are more compact, technologically advanced, and focused on lean manufacturing principles. The integration of computer numerical control (CNC) machines has revolutionized grinding operations by allowing for high precision and repeatability. CNC machines can operate continuously with minimal supervision, thereby reducing the dependency on skilled labor. These machines also allow for the automation of complex tasks, enhancing both speed and accuracy in the production process.

The following table compares some key aspects of traditional and modern grinding room designs:

| Aspect | Traditional Grinding Rooms | Modern Grinding Rooms |

|---|---|---|

| Machinery | Manual, heavy-duty | CNC, automated |

| Labor Dependency | High | Low |

| Precision | Dependent on operator skill | High, consistent |

| Space Utilization | Extensive | Compact, efficient |

| Energy Efficiency | Low | High |

As you can see from the table, modern grinding room designs offer significant advantages over their traditional counterparts, particularly in terms of efficiency, precision, and sustainability. For a visual understanding, check out this informative video: “Modern Grinding Room Innovations” by Manufacturing Tech Insights.

The Role of Technology in Grinding Room Design

Technology plays a pivotal role in the evolution of grinding room design, driving improvements in precision, efficiency, and safety. One of the most transformative technologies is the Internet of Things (IoT), which connects machines and systems, enabling real-time data collection and analysis. This connectivity allows for predictive maintenance, where potential issues are identified and addressed before they lead to downtime. IoT-enabled devices can also optimize energy usage, monitor environmental conditions, and improve overall operational efficiency.

Augmented reality (AR) and virtual reality (VR) are emerging technologies with significant potential in grinding room design. These technologies offer immersive training experiences for operators, reducing the learning curve associated with complex machinery. AR can overlay digital information onto the real world, providing operators with real-time guidance and diagnostics. VR, on the other hand, can simulate entire grinding processes, allowing operators to practice and perfect their skills in a risk-free environment. These technologies not only enhance training but also improve safety and productivity.

Furthermore, advancements in materials science have led to the development of more durable and efficient grinding tools. High-performance abrasives, such as cubic boron nitride (CBN) and polycrystalline diamond (PCD), offer superior cutting capabilities and longer lifespans compared to traditional materials. These advanced abrasives reduce the frequency of tool changes, enhance precision, and contribute to cost savings. The integration of these cutting-edge materials into grinding room designs is a testament to the importance of continuous innovation in achieving optimal manufacturing outcomes.

- Enhance your understanding by exploring more about IoT in manufacturing: IoT in Manufacturing – YouTube Channel: Smart Manufacturing

- Discover the impact of AR and VR in industrial training: AR and VR in Industrial Training – YouTube Channel: Industry 4.0

Key Considerations for Designing an Optimal Grinding Room

Designing an optimal grinding room involves careful consideration of various factors that can influence efficiency and precision. One critical consideration is the layout of the room, which should facilitate a smooth workflow and minimize unnecessary movement of materials and personnel. An efficient layout not only reduces processing time but also minimizes the risk of errors and accidents. Ergonomic considerations are also crucial, as they can significantly impact operator comfort and productivity. Adjustable workstations, proper lighting, and noise reduction measures are essential elements of an ergonomically designed grinding room.

Another key consideration is the selection of machinery and equipment. The choice of machines should align with the specific requirements of the manufacturing process, including material type, required precision, and production volume. Investing in high-quality, reliable machines can lead to long-term savings by reducing maintenance costs and downtime. Additionally, the integration of automation and robotics can further enhance efficiency by streamlining operations and reducing the need for manual intervention.

Safety is paramount in any grinding room design. Implementing comprehensive safety protocols and training programs is essential to ensure the well-being of operators. Safety measures can include the installation of protective barriers, emergency shut-off systems, and proper ventilation to manage dust and fumes. Regular safety audits and maintenance checks are also crucial to maintaining a safe working environment.

Ultimately, the design of a grinding room should align with the overall goals of the manufacturing facility, whether they be maximizing productivity, enhancing precision, or achieving sustainability. By carefully considering these factors and leveraging the latest technological advancements, manufacturers can unlock the full potential of their grinding operations, achieving greater efficiency and precision in their processes. 🌟

Conclusion

Unlocking the potential of innovative grinding room designs is a pivotal topic in the realm of manufacturing and precision engineering. Throughout this article, we have delved into various aspects that underscore the significance of optimizing these spaces for enhanced efficiency and precision. Our exploration has been multifaceted, covering state-of-the-art technologies, strategic layout designs, and the integration of smart systems to revolutionize the grinding process.

Firstly, we examined the importance of incorporating advanced technologies, such as automated machinery and AI-driven systems, in modern grinding rooms. These innovations not only streamline operations but also enhance precision by minimizing human error. The integration of IoT devices allows for real-time monitoring and data collection, facilitating predictive maintenance and reducing downtime. As the manufacturing landscape becomes increasingly competitive, embracing these technologies is essential for businesses aiming to maintain a cutting-edge position in the industry.

Moreover, we discussed the strategic layout of grinding rooms, emphasizing how thoughtful design can significantly impact operational efficiency. By optimizing the flow of materials and personnel, companies can reduce bottlenecks and enhance productivity. The implementation of ergonomic principles further ensures that the workspace is not only efficient but also conducive to employee well-being. This aspect is crucial, as a healthy and motivated workforce directly contributes to the overall success of the manufacturing process.

Additionally, the article highlighted the role of sustainable practices in grinding room design. As environmental concerns continue to rise, adopting eco-friendly solutions is no longer a mere option but a necessity. Energy-efficient machinery, waste reduction strategies, and the use of sustainable materials can all contribute to a greener manufacturing process. These practices not only benefit the planet but also offer long-term cost savings and improve the company’s public image.

In reinforcing the importance of these themes, it becomes evident that the evolution of grinding room design is not just about keeping pace with technological advancements but also about fostering an environment that promotes efficiency, precision, and sustainability. The integration of innovative solutions into these spaces is a testament to the industry’s commitment to progress and adaptation in an ever-changing world.

As we conclude, it is crucial to recognize that the transformation of grinding rooms is an ongoing journey rather than a destination. The rapid pace of technological advancements necessitates continuous learning and adaptation. For industry professionals and enthusiasts, staying informed and open to new ideas is key to unlocking the full potential of these innovative designs. Engaging with peers, attending industry conferences, and exploring academic research are excellent ways to remain at the forefront of developments in this field.

We invite you, our readers, to share your thoughts and experiences on this topic. Your insights are invaluable and contribute to the collective knowledge of our community. Feel free to leave a comment below or share this article with colleagues and friends who might find it informative. By fostering a collaborative environment, we can drive further innovation and excellence in grinding room design.

[Learn more about innovative manufacturing practices](https://www.technologyreview.com/topic/innovation/)

[Explore sustainable design in manufacturing](https://www.greenbiz.com/)

[Stay updated with the latest in precision engineering](https://www.theengineer.co.uk/)

Please ensure the links are still active and relevant to your topic, as URLs and site content may change over time.

Toni Santos is a visual historian and artisan whose creative lens is captivated by the forgotten marvels of antique optical devices. Through his thoughtful storytelling, Toni revives the instruments that once transformed light into wonder—camera obscuras, magic lanterns, kaleidoscopes, and other ingenious tools that shaped our earliest visual imaginations.

His journey is rooted in a fascination with how humans have long sought to bend, reflect, and reveal the unseen. Whether tracing the mechanical poetry of 19th-century projectors or illustrating the tactile elegance of early lenses, Toni’s work invites us to see vision itself as an evolving art form.

Blending handcrafted design with historical inquiry, Toni brings to life the material soul of these devices—celebrating not just how they functioned, but what they meant. His creations and curated stories illuminate a world where science, illusion, and beauty were intricately linked through glass and brass.

As the curator of Vizovex, Toni shares detailed studies, reconstructed artifacts, and immersive content that help others rediscover the origins of visual technology and the magic of analog perception.

His work is a tribute to:

The craftsmanship behind early visual instruments

The wonder of seeing through the eyes of another century

The intersection of optics, art, and imagination

Whether you’re a collector, a designer, or someone drawn to the lost poetry of vision, Toni welcomes you into a world where light is a storyteller—one prism, one lens, one forgotten invention at a time.